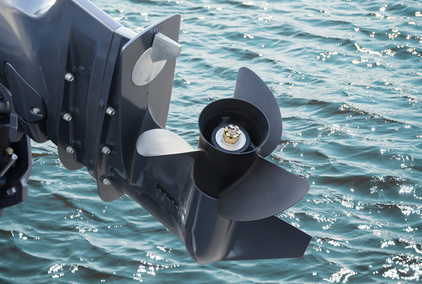

AMS 5936 combines excellent strength, toughness and stress corrosion cracking resistance in the overaged H1000 condition. The high strength levels of the alloy come from a single age hardening step consisting of heating to a selected temperature between 900/1150°F (482/621°C) and holding for four to eight hours. AMS 5936 applications include speed boat propellers, torque tubes, endoscopic instruments, and wire face shields for field sports.