Inconel 601 is a nickel-chromium alloy known for its solid high temperature strength and ability to retain its ductility, even after long service exposure.

The alloy is highly resistant to oxidation up to 2200°F and features ample hot corrosion resistance under oxidizing conditions.

601 is more difficult to machine than 304 stainless steel and is able to resist spalling even under severe thermal cycling by developing a tightly adherent oxide scale.

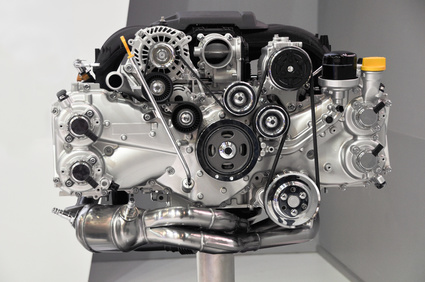

Applications for Inconel 601 include thermal reactors in exhaust system of petrol engines, fabricated combustion chambers, in addition to tube supports and ash trays in the power generation industry.

| AMS Spec | Application |

| AMS 5715 | AMS 5715 is a nickel-chromium-iron alloy built for applications needing a material that is resistant to heat and corrosion. |

| AMS 5870 | AMS 5870 features resistance to oxidation at very high temperatures up to 1250C. |