Alloy 465 is a premium melted, martensitic, age-hardenable alloy known for its ultimate tensile strength in excess of 250 ksi in the overaged (H 950) condition.

This enables the alloy to have excellent notch tensile strength and fracture toughness, in addition to great stress corrosion cracking resistance.

Alloy 465’s corrosion resistance is comparable to 304 stainless and it is typically forged within the temperature range of 1850/2000°F.

465 can be machined in both the solution-treated and various age-hardened conditions.

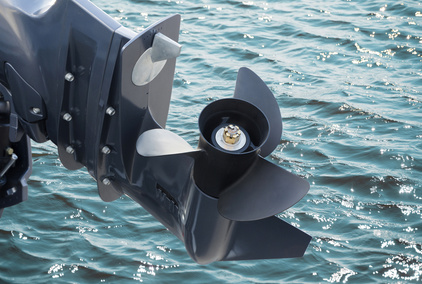

Alloy 465 applications include landing gear components, pneumatic cylinders, suspension coil rings, endoscopic instruments, drive shafts, golf club faceplates, speed boat propellers, and big-bore firearms cylinders.

| AMS Spec | Application |

| AMS 5936 | AMS 5936 combines excellent strength, toughness and stress corrosion cracking resistance in the overaged H1000 condition. |