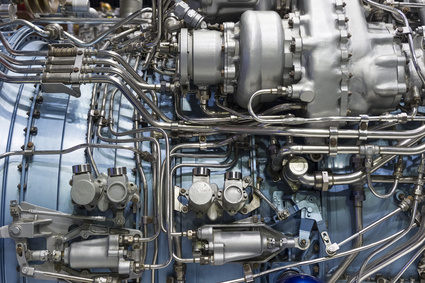

Waspaloy is an age hardening nickel base superalloy characterized by solid oxidation resistance and serviceable strength at temperatures up to 1400-1600°F.

While Waspaloy’s creep-rupture strength is better than that of alloy 718 at temperatures higher than 1150-1200°F, Waspaloy’s short time hot tensile strength is inferior to 718 at temperatures up to 1350°F.

Welding is hard to do but is possible as long as Waspaloy is in the solution annealed condition.

The alloy’s high strength and oxidation resistance to 1750°F make it perfect for shafts and fasteners, gas turbine components, missile systems, and airframe assemblies.

| AMS Spec | Application |

| AMS 5544 | AMS 5544 is a nickel based age hardenable alloy featuring good corrosion resistance, particularly to oxidation. |

| AMS 5586 | AMS 5586 is characterized by high temperature strength and commonly used in critical rotating applications. |

| AMS 5704 | AMS 5704 is a precipitation hardening, nickel-based alloy requiring considerable strength and corrosion resistance at temperatures up to 1600°F (871°C). |

| AMS 5706 | AMS 5706 features excellent corrosion resistance and is typically used at temperatures up to 1600°F. |

| AMS 5707 | AMS 5707 is an age hardening nickel base alloy perfect for use in temperatures up to 1400-1600°F. |

| AMS 5708 | AMS 5708 is features greater creep rupture strength than that of alloy 718 at temperatures above 1150-1200°F. |

| AMS 5709 | AMS 5709 is known for its good corrosion resistance to oxidations. |

| AMS 5828 | AMS 5828 is a precipitation hardening, austenitic nickel-base alloy typically used in elevated temperature applications. |